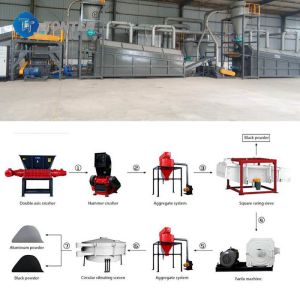

Ternary Lithium Battery Crushing Separation NiMH Battery Recycling

Machine

Product introduction:

The recycling and crushing production line of ternary lithium

battery and nickel-hydrogen battery is the key equipment for

battery recycling and processing. The production line mainly

includes conveyor, crusher, screening machine, magnetic separator

and other components. The crusher is a device that breaks the new

energy battery into small pieces, the screening machine is to

screen the crushed battery and separate the materials of different

particle sizes, and the magnetic separator is to separate the

magnetic substances in the battery.

Working principle:

The waste lithium battery recycling and processing equipment is

based on the material characteristics of the positive and negative

structures of lithium batteries and their constituent materials

copper and carbon powder. Through the combined process of hammer

vibration crushing, vibration screening and airflow sorting, the

resource utilization of metal copper and carbon powder in the

negative materials of waste lithium batteries can be realized.

The negative material can effectively realize the mutual peeling

between carbon powder and copper foil after hammer vibration

crushing, and then the copper foil and carbon powder can be

initially separated by vibration screening based on the size

difference and shape difference between particles. The results of

hammer vibration stripping and screening separation show that

copper and carbon powder are enriched in the particle size range

greater than 0.250 mm and less than 0.125 mm, respectively, and can

be directly recycled.

For crushed particles with a particle size of 0.125~0.250 mm and a

low copper grade, airflow sorting can be used to achieve effective

separation between copper and carbon powder

The ternary lithium battery crushing and separation nickel-hydrogen

battery recycling machine mainly adopts physical recovery methods,

which has the characteristics of green, low carbon, and secondary

pollution, and takes into account economy and benefits, realizing

the utilization of valuable components and treating harmful

components. The entire recycling process has achieved industrial

automation, with high recycling efficiency and strong processing

capacity.

Process:

Conveyor-Shredder - Hammer Crusher -Grinder -Separation -Pulse Dust

Collector -Classifying Screen-Magnetic-Gravity

Separator-High-pressure Blower

Lithium battery recycling line specification:

Items | LR-1250 | LR-1560 | LR-1800 |

Production capacity | 500-800Kg/h | 800-1000Kg/h | 1000-1500Kg/h |

Motor power | 78Kw | 115 Kw | 135 Kw |

Weight | 3.6 Ton | 5.7 Ton | 8.2 Ton |

Dimension (m) | 16x4.6x3.2 | 20x6.2x5 | 22x6x5.1 |

Customer site: